Our Men of Property, 1846-1892

Our trade has left us and it will continue to do so. Last fall a great many of the farmers from the towns of Montgomery and Crawford, and Minisink sent their produce and butter to market by the Erie Rail Road from Goshen, and next May when that railroad is finished to Middletown, we must expect to lose all the trade of those towns. How shall we make up the loss? Why do not some of our men of property take measures to have manufacturing establishments erected on our wharves? -The Newburgh Journal, February 18, 1843

On an early Monday morning in August 1845, a great bell roused the residents of the northeastern section of Newburgh. Those who lived on the steep banks of the Hudson peered towards the waterfront, and although the sun had not cleared the mountains to the east, it was possible to discern a steady stream of people mostly nervous young women-crossing a footbridge to the sixth story entrance of the new cotton factory. The scene was strangely evocative of the previous day when hundreds of people responded to the summons of church bells throughout Newburgh. But the call of God was noticeably less strident than that of the factory, for the factory bell continued throughout the day and into the “still hours of the night.” Despite the complaints of the townspeople, the clamor persisted during the days and weeks to come, relenting only on the Sabbath. The factory then – and only then – acceded to the less temporal demands of the church.1

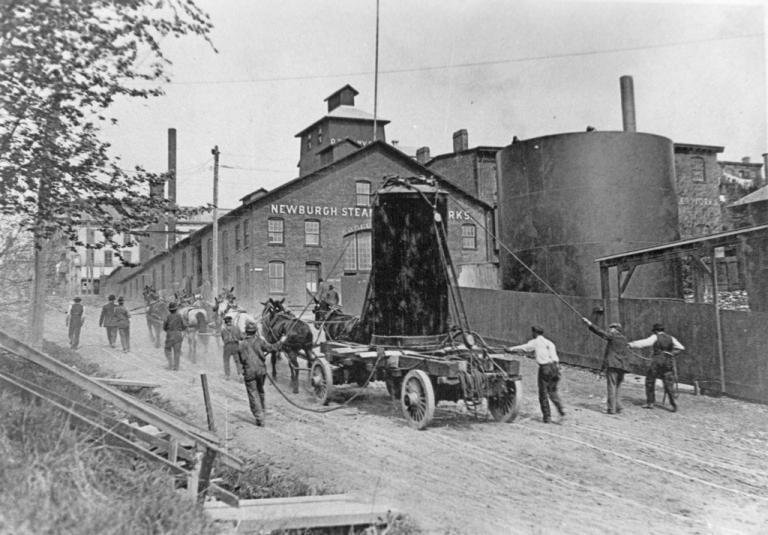

The factory bell eventually fell silent, its deep sonorities replaced by the shrill sound of the steam whistle. In the cotton factories of New England, established some fifteen to twenty-five years earlier, the great bell was a reflection of the avowedly religious aspiration of the factory founders as well as a useful means of mass communication. 2 But in Newburgh there was no technological explanation for the factory bell; unlike the water-powered cotton factories of New England, the Newburgh Steam Mills – as proclaimed by its corporate name – employed a new source of power: the steam whistle was available from the outset.

Why were the Newburgh Steam Mills equipped with an innovative and unproven power source? Indeed, why was there a cotton factory in Newburgh at all?

It is impossible to give straightforward answers to these questions; the local newspapers and histories scarcely touched on the subject. But this much is known: Homer Ramsdell, Thomas Powell, Benjamin Carpenter, David Crawford, Christopher Reeve, and several other freighters invested a total of $100,000 to establish the Newburgh Steam Mills in the spring of 1844.3 In so doing Newburgh’s main forwarding merchants shed their mercantile vestments and donned those of the industrialist. They had learned the ritual from others, most notably the merchant princes of New England-Francis Lowell, Nathan Appleton, and Amos Lawrence-who had abandoned trans-Atlantic trade and had built scores of cotton textile factories throughout New England during the 1820s and 1830s. Confronted with a similar economic crisis, Newburgh’s freighters carefully repeated each detail of the ceremony: they patterned their corporate charter after the New England companies, they differentiated each floor of the factory by production function, and they copied the architecture of the earlier factories, including even the cupola and bell. Insofar as Newburgh’s freighters imitated the great merchants of New England, it is useful to review the rise of the cotton textile industry in that region to understand the motives of Newburgh’s freighters.

The merchants of the major port cities of New England initially decried the development of domestic manufacturers, arguing that local factories destroyed more jobs in foreign trade than were created in manufacturing.4 The antipathy of the merchants towards manufacturing was founded in a belief that the activities were inherently competitive; a self-sufficient economy, they reasoned, had little need for trade. The most prosperous merchants also believed that manufacturing inevitably culminated in the emergence of grimy mill towns populated by a dispirited working class. Furthermore, the well-publicized failure in the early 1800s of a large cotton factory in Beverly, Massachusetts convinced most New England merchants that their opposition to domestic manufacturing was well-founded.5

However, the War of 1812 and the subsequent decline of the Atlantic maritime trade altered both the opinions and profit margins of the New England merchants. Men who had reinvested surplus capital in mercantile pursuits began to look for more lucrative investments; their search led them to upland New England, where swift-flowing rivers could provide the power for textile machinery. Throughout New England, merchants began to redirect capital into cotton textile manufacturing. In places such as Lowell, Lawrence, and Chicopee, Massachusetts – where there was no pre-existing town to speak of – they built workers’ housing, schools, and churches and extended rail lines to establish an uninterrupted flow of raw materials and finished cloth. Yet these impressive efforts at city-building on the part of the prominent merchants of Boston were but the most visible examples of a general mercantile transition to cotton manufacturing in New England during the 19th century.6

While the decline of oceanic trade in the early 1820s provided the incentive for New England’s merchants to build cotton textile factories, the impact of the Erie Railroad in the early 1840s caused a similar economic transformation of Newburgh. And much as the merchants of New England initially opposed the development of local manufacturers, the forwarding merchants’ main concern from the outset was to block the Erie Railroad and to maintain the existing commercial network. But the completion of the railroad to Goshen in 1841, which provided Orange County farmers with easy access to New York City markets, signaled the end of Newburgh’s mercantile heyday. The freighters decided to recast Newburgh’s economic base, and the cotton factory was the first step in this process. The cotton textile industry had initiated the industrial revolution in Great Britain in the late 18th century and New England in the early 19th century; Newburgh’s forwarding merchants hoped it would do the same for their town in the 1840s.

The construction of a massive cotton factory by Newburgh’s forwarding merchants was, above all else, an act of faith. It stemmed from the conviction that the world of the future was to be shaped by coal, iron, and machines, a conviction, moreover, that the great merchants of New England had discovered the way to that world. Newburgh’s freighters-turned-manufacturers, like any novitiates, scrupulously patterned their efforts after their mentors – Lowell, Appleton, and Lawrence.

But there was one significant difference: the machinery in the Newburgh cotton factory was powered by steam engines. Although a handful of cotton factories made use of steam engines before 1844, water-powered mills remained a characteristic feature of New England textile manufacturing until well after the Civil War.7 Since Newburgh’s forwarding merchants had imitated the merchant-manufacturers of New England on so many other matters, why did they choose an innovative and unproven power source?

If their main objective was to profit directly from cotton manufacturing, they could have invested in established New England firms or built a more conventional water-powered factory in nearby Walden.8 Yet they located the cotton factory in Newburgh, and this was made possible by the availability of the still-experimental steam engine. The cotton factory was sited on the riverfront, not for access to water power (the Hudson was slow-moving) but to make use of the freighters’ idled steamboats to carry raw cotton and finished goods to and from the factory’s clocks. Should the cotton factory fail to return a dividend, increased freighting revenues might compensate for any losses in manufacturing, much as the old turnpikes had contributed to the wealth of the merchants without ever turning a consistent profit themselves. Newburgh’s freighters believed, more over, that the factory would repopulate the village, quicken the pace of business, and most important, increase the value of their lands.

The directors of the Newburgh Steam Mills had little difficulty finding the men and women to take the low-paying jobs as loom and spinning machine operators. Although the crisis precipitated by the Erie Railroad forced hundreds of Newburgh artisans and craftsmen to seek opportunities elsewhere, nearly as many unskilled Irish laborers were enticed to Newburgh by the lower cost of living (especially the cheap rents) caused by the local depression of 1841 to 1845. And if the forwarding merchants had misgivings over the social impact of the cotton factory, the severity of the local economic crisis overcame them.

The cotton factory succeeded in sparking Newburgh’s industrial development. Whereas the largest previous manufacturing firm employed at most twenty-five workers, the cotton factory listed over three hundred employees, most of them women.9 The cotton factory also gave rise to what was known as the “cotton complex,” a clustering of cotton mills with nearby iron foundries. The first large local foundry specialized in producing steam engines, looms and other machinery designed for cotton mills,10 presumably the Newburgh Steam Mill was its major source of demand. Newburgh’s forwarding merchants played an important role in developing these subsidiary industries. Benjamin Carpenter and his brother built the town’s first major iron foundry while Homer Ramsdell established the Washington Iron Works.

However, the rise of Newburgh’s metal and machinery industries pointed up the town’s inadequate transportation. If Newburgh was to become an industrial city, it needed access to the coal fields of western Pennsylvania and the iron ore of areas farther west. The freighters became convinced that Newburgh’s nascent industries required rail connections, and they renewed efforts to attain that objective.

Ironically, the Erie Railroad gave the freighters their chance. Although the railroad was unfinished in 1840, the Erie had exhausted the initial State loan; despite intense criticism, it applied for yet another. Thomas Powell and Homer Ramsdell, heading a delegation of local forwarding merchants, worked with state representatives to block relief legislation for the Erie Railroad. Ramsdell eventually proposed a compromise which the Erie accepted in 1845: the Erie would build and operate a special railway spur from Goshen to Newburgh and a Newburgher would serve as a director of the corporation. In return, Newburgh’s freighters were to renounce the charter of the dormant Hudson and Delaware Railway, to support the legislative aims of the Erie, and to raise #140,000 for the construction of the spur. With Newburgh’s support, the relief legislation passed. By 1849 the forwarding merchants had raised the necessary funds (see Table 1) and the spur was completed within two years. Newburgh, at last, had access to the coal and iron of the Midwest.11

TABLE 1

Mercantile contributions to the Newburgh spur of the Erie

| Firm | Amount |

| Thomas Powell & Co.” | $45,000 |

| Benjamin Carpenter & Co. | 10,000 |

| Crawford, Mailler & Co. | 25,000 |

| John P. DeWint | 25,000 |

| N. Reeve | 1,000 |

| $106,000 |

Not listed above is a $25,000 contribution of the Beveridge Brewing Company which often acted in consort with the freighters. In all, Thomas Powell and his son-in-law, Homer Ramsdell, made land purchases and cash advances to the Erie that totaled $202,219. Source: Rutenber, History of Orange County, pp. 120-121.

With the support and guidance of the forwarding merchants, Newburgh’s industrial development proceeded rapidly. From 1844 to 1879 Newburgh’s value added by manufacturing (adjusted for price fluctuations) increased ten-fold (see Table 2).

TABLE 2

Value added by manufacture for Newburgh, 1839-1899, adjusted to 1879 prices

| Year | Value added by manufacture | Value-added price deflators” | Value added by manufacture |

| (current prices) | (1879= 100) | in 1879 prices | |

| 1839b | 87,550 | 126 | 54,246 |

| 1844 | 106,750 | 107 | 99,766 |

| 1849 | 470,109 | 92 | 510,988 |

| 1854 | 541,600 | 98 | 552,653 |

| 1859 | 701,480 | 95 | 738,400 |

| 1869 | 1,162,485 | 151 | 769,858 |

| 1879 | 1,035,480 | 100 | 1,035,480 |

| 1889c | 2,403,000 | 90 | 2,670,000 |

| 1899c | 2,764,500 | 81 | 3,455,625 |

“Based on Robert E. Gallman, “Commodity Output, 1839-1899.” in the National Bureau of Economic Research, Trends in the American Economy in the 19th Century, Vol. 24, (Princeton University Press. 1960). p. 56. Deflators were rounded to the nearest whole number.

‘The 1839-1840 Census Schedules for Newburgh are missing. The 1839 Value added figures were interpolated from 1835 and 1845 data.

‘The Manuscript Schedules for Manufacturing for 1889 were destroyed by fire. The data for Newburgh for 1889 and 1899 were derived from published schedules of manufacturing and are not necessarily comparable to the earlier figures. Source: Refer to Appendix B.

Newburgh’s transition from a commercial village to an industrial city was further reflected in a change in the nature of its manufactures. In 1835 eighty-five percent of Newburgh’s value added by manufacturing derived from the town’s commercial functions: Local breweries, gristmills, tanneries and sawmills processed the grain, animal skins and timber of nearby farmers; in all cases the manufacturing process resulted in a substantial weight loss, thereby reducing freight charges considerably. Yet within ten years of the establishment of the cotton factory, sixty-one percent of Newburgh’s value added by manufacture came from the industries associated with the cotton complex – cotton textiles and metal machinery. By 1880 commercerelated manufactures accounted for less than fifteen percent of Newburgh’s manufacturing output (see Table 3).

TABLE 3

Distribution of Newburgh’s value added by manufacture by industry,1835-1880 (by percent)

| Type of | |||||||

| Type of Industry | 1835 | 1845 | 1850 | 1855 | 1860 | 1870 | 1880 |

| Iron Foundries and

metal machinery |

14 | 7 | 30 | 21 | 29 | 46 | |

| Textiles | 14 | 24 | 31 | 31 | 28 | 20 | 14 |

| Clothing | I | 10 | 14 | ||||

| Gristmills and

brewing |

72 | 36 | 20 | 8 | 18 | 13 | 1 |

| Sawmills, wooden

items |

4 | 9 | 14 | 12b | 13 | 4 | |

| Leather products | 9 | 22 | 9 | 16a | 8a | 3 | 9a |

| Mineral processing | 1 l | 1 | |||||

| Chemicals | 2 | 8 | |||||

| Miscellaneous | 1 | 4 | 13 | 19 | 10 | 9 | 3 |

Includes soap manufacturing, which was largely dependent on animal fat and accordingly was grouped with leather products. By 1880, the figure represents solely soap manufacturing. lncludes some other construction materials.

Sources: The Federal Census Schedules for Manufacturing for 1850-J 880 and the Manuscript Schedules for the New York State Census for 1835, 18 45, and 1855. The 1840 Federal Schedule is no longer available while the J 865 and 1875 State Censuses were incomplete.

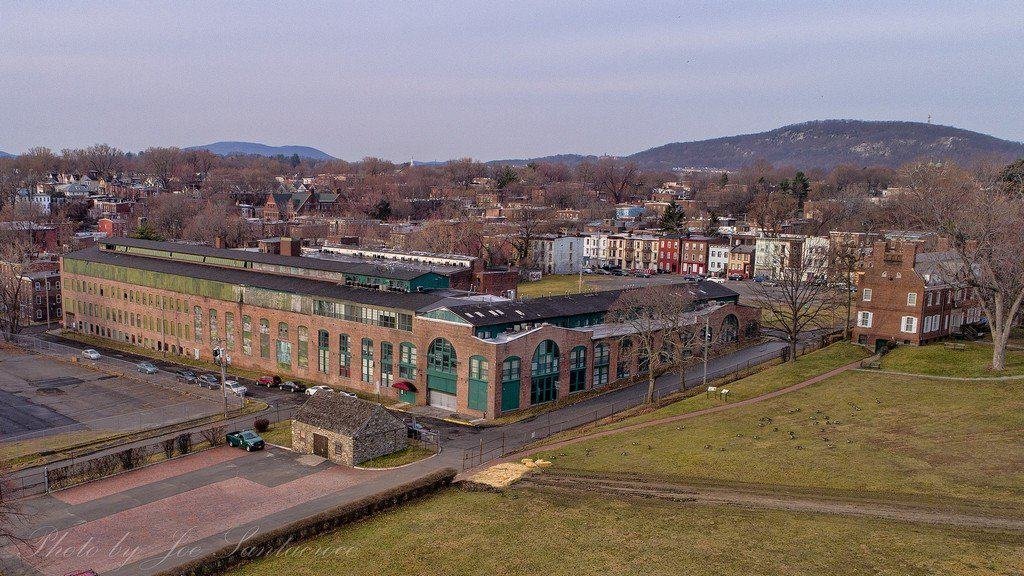

Accompanying the shift in Newburgh’s economic base were changes in its physical structure. Prior to the mid-century industrial transformation, the built-up area was concentrated along a half- mile section of the riverfront (refer to Map 1; the heart of the old village is screened). Surrounding this commercial and residential district were the estates of the forwarding merchants. After the completion of the Newburgh railroad spur, Newburgh’s industrialists were no longer obliged to site their factories along the riverfront, and the proliferation of factories to the south and west of the old village reflected this change in transportation. Homer Ramsdell, anticipating the direction of Newburgh’s industrial development, purchased large sections of land abutting the Erie spur; by the time of the Civil War, he had erected several factories and leased them to promising entrepreneurs.

mile section of the riverfront (refer to Map 1; the heart of the old village is screened). Surrounding this commercial and residential district were the estates of the forwarding merchants. After the completion of the Newburgh railroad spur, Newburgh’s industrialists were no longer obliged to site their factories along the riverfront, and the proliferation of factories to the south and west of the old village reflected this change in transportation. Homer Ramsdell, anticipating the direction of Newburgh’s industrial development, purchased large sections of land abutting the Erie spur; by the time of the Civil War, he had erected several factories and leased them to promising entrepreneurs.

Although it is not known for certain that the forwarding merchants initiated Newburgh’s industrialization to drive up real estate prices, that was an important consequence of their actions. The old residential section of Newburgh failed to accommodate the rapidly expanding industrial population, and new streets and housing tracts were built to the south and west (refer to Map 1; the dotted lines indicate street extensions between 1835 and 1879). The census schedules of 1870 listed Isaac Van Duzer’s son as owning $65,000 in real estate while Benjamin and Isaac Carpenter (the latter describing himself as a “speculator in real estate”) owned $210,000. Unequaled, however, were the landholdings of Homer Ramsdell which reportedly totaled $714,500. The lands of Henry Robinson purchased for approximately $250 per acre in 1835, were subdivided by developers and sold by the lot for what amounted to $4,000-5,000 per acre in 1887.

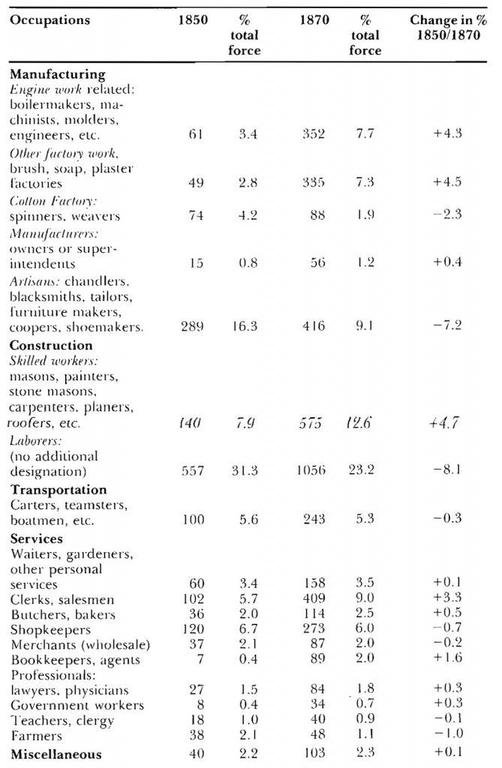

Rising land values are often an indication of an increasing population, but as Newburgh industrialized, there was a change in the nature as well as the size of the town’s labor force. As a commercial center, Newburgh’s workforce largely consisted of the craftsmen who tended to the needs of the visiting farmers. With the depression that followed the construction of the Erie Railroad, however, these artisans were the first to seek opportunities elsewhere. It is impossible to calculate precisely the extent of this demographic dislocation since the census schedules prior to 1850 failed to list detailed occupational information about the Lawn’s residents. Information from 1850 to 1870 confirms the expected decline in the importance of craftsmen in Newburgh’s economy (see Table 4).

TABLE 4

Occupational distribution of male workers in Newburgh, 1850-1870

| Occupational group by sector | 1850 total |

% male labor force | 1870 total |

% male labor force | Percentage change 1850-1870 |

| Manufacturing

Factory work |

199 |

11.2 |

831 |

18.2 |

+ 7.0 |

| Artisans | 289 | 16.3 | 416 | 9.1 | – 7.2 |

| (sub-total) | (27.5) | (27.3) | (-0.2) | ||

| Construction | |||||

| Skilled | 140 | 7.9 | 575 | 12.6 | +4.7 |

| Laborers | 557 | 31.3 | 1.056 | 23.2 | -8.1 |

| (sub-total) | (39.2) | (35.8) | (-3.4) | ||

| Transportation | 100 | 5.6 | 243 | 5.3 | – 0.3 |

| Services | 493 | 27.7 | 1,439 | 3J.6 | + 3.9 |

Source: Original manuscript Census Schedules of Population for Newburgh for 1850 and 1870.

The occupational statistics also indicate the importance of construction in Newburgh’s mid-century economy. Industrial growth created a demand for new factories, houses, tenements, sewers, water lines and other types of construction, and by 1870 nearly twice as many men were employed in construction as in factory production. For these construction workers and general laborers a healthy Newburgh was, by definition, ever growing; if industries failed to grow, or if new industries did not move to town, the demand for residential and industrial construction would dry up. Due to the magnitude of the construction sector, the town was confronted with paradox: Newburgh could maintain its population only through growth.

Newburgh’s industrial transformation thus marked a change in emphasis from external to internal growth. When Newburgh functioned as a commercial center, its forwarding merchants exploited the economic potential of the hinterland; their concern was not with the growth of Newburgh per se, but with the expansion of the outlying agricultural region. But to protect their commercial and real estate holdings, the freighters chose to exploit the internal aspects of Newburgh’s economy. Once set in motion, their economic system was apparently self-sustaining: industrial growth brought new factory workers who required housing which in turn led to a further expansion of the construction and service sectors of Newburgh’s economy.

It seems unlikely that many Newburghers initially shared the forwarding merchants’ sense of localism, which had derived from marital ties and real estate investments. But by mid-century, this largely private attachment to Newburgh had evolved into a pervasive and strident boosterism. The people of Newburgh seemed to be aware of the subtle balance of the town’s economic mechanism, for a failure to grow would generate a retrogressive cycle: an exodus of construction workers, less consumer demand. reductions in the service sector, still less construction and so on. Since over thirty-five percent of Newburgh’s families owned their homes, the economic decline of the city would spell financial ruin for the town’s middle classes. The promotion of Newburgh became not a stratagem for a few, but the fundamental concern of the entire community.

As the commitment to Newburgh-to localism-was becoming widespread, the forwarding merchants began to relinquish their pre eminent position in the community. A grateful population accorded them honors testifying to the success of their plan of development; main streets were named after Powell, Carpenter, Robinson, Walsh, and Smith (Ramsdell no doubt disdained the comparison implicit in such an honor).

But the task of sustaining Newburgh’s growth was left to a new generation of entrepreneurs, mostly industrialists. These new men immigrant machinists with a gift for invention, or self-made entrepreneurs with lots of energy and optimism – were eager to superintend Newburgh’s continued growth. Robert Whitehill, born in Glasgow, worked in a Newburgh foundry. As an apprentice, he invented a machine for sizing and dressing cotton yarn, and by 1890 was president and chief owner of several large machinery factories. Patrick Delany, a refugee from the Irish potato famine, could tell a similar story: He worked in a boiler works, devised several patents and established his own factory. Horatio Beckman began as a machinist in Newburyport and invented a machine that “revolutionized the entire comb trade”; he became long-standing superintendent of the Newburgh Steam Mills and a major stockholder in the local electric company. A final example of this new generation is William Wright, who purportedly invented the nation’s first rotary engine at the age of twenty-seven; armed with a handful of patents and an impressive reputation, Wright gained Ramsdell’s support and opened the town’s largest machine factory.12 ·

The visible success of these self-made men made them natural heirs to the forwarding merchants’ legacy of town promotion. Although these inventor-entrepreneurs were newcomers, the town accepted them almost immediately. Whitehill was elected alderman and chosen as president of the Board of Trade; Delany, too, was elected alderman; Beckman served as water commissioner and alderman; Wright became the most prominent member of the Board of Trade. Newburgh’s “society” also opened ranks to admit these ostensible parvenus: Wright, Whitehill, and Beckman were charter members of· Newburgh’s prestigious private club.13

While the forwarding merchants’ concerted efforts to “boost” Newburgh were strongly influenced by their substantial investments in local real estate, the localism of the subsequent generation of manufacturers can best be understood as the result of social rather than economic factors. They sought status and promised economic growth in return. An indication of the manufacturers’ good faith was the formation of the Board of Trade in 1882 which symbolized the shift from the collective entrepreneurship of the old freighters to a more formal collective entrepreneurship of manufacturers.14

By 1891 it was clear that the forwarding merchants had succeeded. Townspeople celebrated the rise of their industrial city by subscribing to a new history of the city. John Nutt, the town biographer, emphasized in 1891 the parallel of Newburgh’s industrial growth with its period of turnpike expansion under the leadership or the early freighters; in his words, “the tidal wave of prosperity that swept over the village a hundred years ago has returned.” United in purpose and infused with a sense of localism, the people of Newburgh acclaimed the achievements of Whitehill, Wright, Delany, Beckman, and others, and anticipated “a new era” of expanded growth. Nutt concluded, “All the indications are that the growth is healthy. There is every reason to expect the continuance of the ‘good times.’ The situation and advantages of’ the place are now such that it is not likely to lose its share of good things going.”.15

A Slow Appearance, 1893-1900

| A stranger from Middletown: | “Isn’t Newburgh rather slow, it seems to be falling behind.”

|

| Newburgher:

|

“No; the conditions have changed. The city has lost its old rime com mercial buzz. and is engaged in manufacturing. Hence, we do not see so many people on the streets as we did. Manufacturing towns always have a slow appearance during the clay.”

|

–Newburgh Sunday Telegram, September 23, 1900

It seemed that only an astute outsider, making periodic visits, could have perceived the dimensions of change that occurred in Newburgh during the closing decades of the 19th century. The built portion of the city had surmounted the crest of hills to the west and began to spill onto the estates of the old forwarding merchants. The Newburgh and Cochecton Turnpike, once the chief artery of hinterland trade, was renamed “Broadway” and began to compete with the older commercial streets along the riverfront. Streetcars, initially drawn by horses, connected the growing residential areas with the factories near the river. Those who walked to work found the going somewhat easier as storm drains and stone pavements graced a number of the more-traveled streets that were formerly inundated by mudslides each spring.

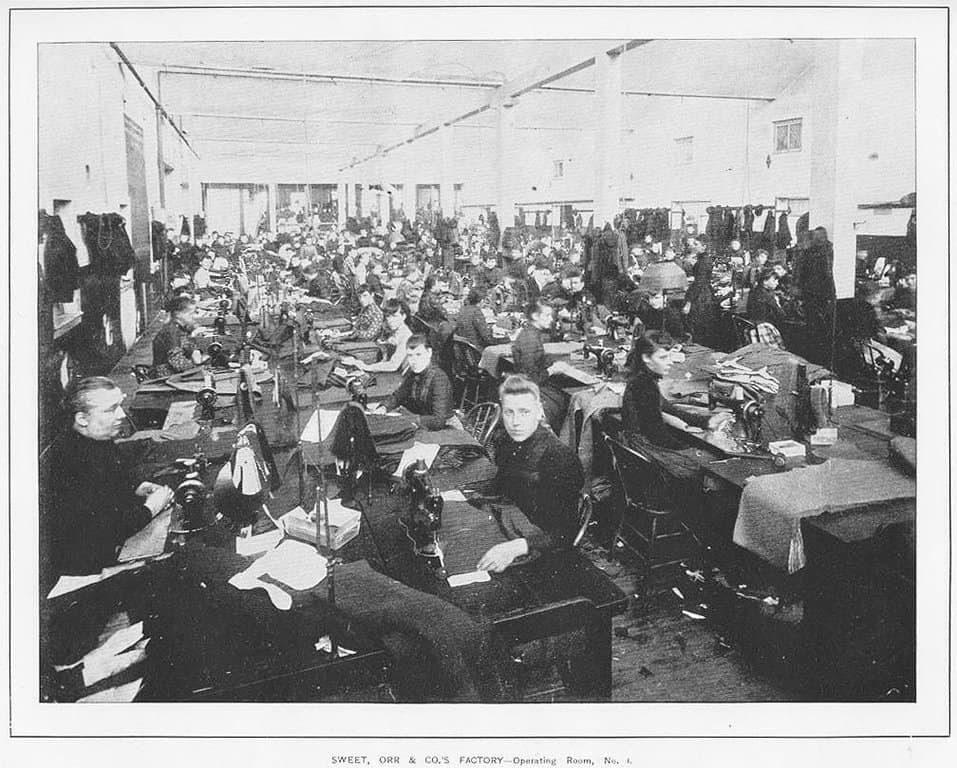

But as the stranger from Middletown observed, even these main thoroughfares were remarkably quiet during the day. Was Newburgh “falling behind”? Had it succumbed in some mysterious way to external competitive pressures? Or were the protestations of the Newburgher substantially correct? The Newburgher didn’t explain exactly why manufacturing towns had a slow appearance, but perhaps he was referring to the large percentage of women in the labor force. Or perhaps the daily round of shopping that had absorbed the attentions of housewives was increasingly being postponed until later in the day as more women went to work in the new garment factories. Or perhaps the Newburgher was thinking of the absence of artisans-displaced by factories and retail scores-who had combined production and retail functions while tending to the needs of the backcountry farmers. But if Newburgh appeared to be falling behind in 1900 there was an alternative explanation:

For several decades Newburghers had been uneasy over the fate of the Newburgh Steam Mills, which in 1813 had initiated the city’s transformation from a mercantile to a manufacturing city. By 1850 the forwarding merchants who had built the cotton factory sold it to Garner and Company of New York City. This firm was mostly owned by Thomas J. Garner, an English millionaire who exported and marketed inexpensive American cotton textiles. To ensure that he could fulfill contracts with European textile merchants, Garner acquired upstate New York cotton textile factories. He soon owned majority stock in the Harmony Mills (Cohoes). the Rocky Glen Company (Dutchess County), the Franklin Dale Company (Clinton County), the Haverstraw Print Works, the Ingham Mills Print Works-and the Newburgh Steam Mills. When Garner died in 1867 he had gained full ownership of the Newburgh factory. His son, though, was fond of yachts and fancy homes, and he neglected the business. By the early 1870s the directors of the Newburgh Steam Mills, appointed by Garner, were loaning Garner and Company large sums of money with that firm’s paper as collateral. The younger Garner died in 1876 and left Garner and Company to his nine-year-old daughter. The will provided that four executors would manage the estate until 1892 when his daughter would attain the age of twenty-five. Two of the executors were dead when the will was read. One of the others, William Thurn, lived in Newburgh and had supervised Garner’s interests there. As executor, Thorn appeared to take pains to protect and expand the Newburgh Steam Mills. Perhaps Thorn’s efforts were too zealous, for Garner’s widow sued Thorn for dissipating the family’s fortune. Eventually, the suit was withdrawn, but when the daughter turned 25 – in 1892 – she closed the Newburgh Steam Mills.

The following year would be worse. The Panic of 1893, and the depression that followed were disastrous for Newburgh. In July the Whitehill company declared bankruptcy, followed by the Wright Engine Works four months later.16 In April 1894 the Delany boiler shop reported that only ten of its employees remained on a payroll that at one time had approached one hundred.17 During the following years, a number of’ other manufacturing firms failed, the most embarrassing being the pride of the Board of Trade: the Kilmer Wire Works.18 Newburgh’s industries had been buffeted by other depressions, especially those following the financial panics of 1857 and 1873, but in general, they had lasted only briefly and were regarded simply as resting points along the march of industrial progress. But the metal and machinery industries of Newburgh were in a weak position even before the Panic of 1893.19 The local firms were neither large enough to make use of scale economies nor located sufficiently near raw materials to achieve savings in transportation.

Although Newburgh’s industrial development was initiated by the cotton factory, the metal and machinery industries soon accounted for the greater part of the city’s industrial output. More important, the metal and machinery firms were “male-employing” as contrasted to the cotton factory and the newer garment factories that relied on cheap female labor.20 The machinists, boilermakers, and molders earned two to three times more than the semi-skilled laborers or construction workers.21 Thus, the insolvency of Whitehill’s, Wright’s, Kilmer’s and other companies precipitated a severe economic crisis.

Within five months of Wright’s closing, between five and eight hundred people left Newburgh, “the vacant houses and apartments being silent witness to the truth of this statement.”22 One newspaper reported that nearly six hundred skilled workers were unemployed,23 while the “best mechanics” – the· molders and machinists – had left town in search of work in the Midwest.24 Despite the exodus of skilled workers. newspaper estimates of the number of unemployed ranged from 1400 to 4000, the latter amounting to nearly fifty percent of the entire workforce.25

What had begun as an industrial crisis quickly spread to other branches of Newburgh’s economy; residential and industrial construction came to a standstill, throwing still others out of work.26 As increasing numbers of wage earners found their jobs eliminated or their wages reduced, the city’s retail trade deteriorated. Pressed to extend credit to their unemployed customers, the proprietors of the nearly two hundred grocery and liquor stores found it difficult to maintain their businesses; a large number of retail stores, both small and large, failed.27 Espousing a Darwinian solution, the Sunday Telegram claimed that the city would be better served if’ ten percent of the stores went out of business or moved elsewhere?28

Relocation, however, was an option that most Newburghers found untenable. Many had invested their lives and their money in establishing their shops. Others owned homes that could now be sold only at a great loss. Still, others thought the prospect of breaking family and neighborhood ties unbearable. Most Newburghers believed, furthermore, that the situation could improve, and they thought it the duty of the town’s leaders to set that process in motion. After all, had not the experience of the previous decades proven that change comes from within? A city grows not because of its inherent locational advantages, but because its leaders possess the vision and enterprise to exploit whatever potential does exist. Indeed, the crisis brought about by the Erie Railroad in the 1840s motivated the Ramsdells, Powells, Carpenters, and Crawfords to build an industrial city. The current crisis, they reasoned, must have been the fault of the new leaders – the Wrights, Whitehills, Beckmans, and Delanys for, as one paper complained, “the old aggressive spirit of development seems to have died with Homer Ramsdell.”29

Money, as well as leadership, was needed to bring about economic recovery. During the two years following his declaration of bankruptcy, William Wright appealed to local sources to raise the $10,000 necessary to satisfy the Engine Works’ main creditor. a “rapacious” New York City bank. Wright noted that if he were able to commence operations he would rehire two hundred “resident mechanics” and thereby inject $10,000 in wages into Newburgh’s prostrated economy each month. But owing to what Wright termed “the indifference of the moneyed class of the city,” his efforts failed. As the elate for the public sale of the Engine Works was set-July 18, 1895 -Wright bitterly complained that if Homer Ramsdell were still alive he never would have had to “beg” for the money to put his firm back in order.30

Whitehill encountered similar problems and was forced to put his factory up for sale at public auction two days prior to the sale of the Wright Engine Works. A syndicate of outside creditors had become dissatisfied with the actions of a locally appointed receiver and had begun to pressure the local judge to dispose of the firm’s remaining assets more equitably.31 A number of prominent Newburghers reasoned that once the firm was sold there would be ”no doubt of its prompt transfer to local interests and immediate resumption.”32

The auction took place in the office of the factory with scores of “capitalists, machinists and workmen” milling around outside awaiting word of the disposition of the old enterprise and the plans for the new. What developed inside was a heated struggle between “local capital” and “New York money,” the former being represented by Whitehill and his friends, the latter by the major New York City creditors. A third faction, headed by Colonel William Dickey (a major real estate speculator in the Heights section of the city) began to bid with the others, but soon dropped out, overawed by the “display of New York money.” The New York faction, “exhibiting the dash and nerve that is characteristic of their city” and led by a member of the Whitney family, gained ownership of Whitehill’s factory. They departed the city close-mouthed about their plans.33

As the New Yorkers descended towards the railroad terminal, Whitehill, Dickey, and the other local capitalists, as well as the machinists and laborers, no doubt wondered whether the people of Newburgh still possessed the resources and leadership necessary to control their city’s destiny. The sale of Wright’s two days hence loomed ominously in their minds, and the belated and clumsy efforts of the Board of Trade to found a joint-stock company to preserve the local factory seemed especially disheartening.34 As was the case with Whitehill, Wright had amassed a number of short-term commercial notes which could not be repaid as orders slackened with the onset of the industrial depression. Wright’s decision to pay his workers and “other local creditors” just before declaring bankruptcy exacerbated the wrath of the firm’s creditors.35 On the day of the sale, the same gathering of Newburghers that had watched the departure of the Whitney group no doubt Flinched as a company of well-dressed people emerged from the New York train and climbed the hill towards the courthouse. Once again Colonel Dickey, with representatives of the Newburgh Real Estate Company, commenced the bidding after proclaiming his intention to start the shop, rehire the workers, and place Wright back in charge. But the Newburghers were outbid by the New York creditors. Wright’s, too, became the property of absentee owners. Observing that “the idea that Newburgh people may be called into the concern seemingly exists more in hope than in material substance,” the Sunday Telegram complained that “local capital lost its opportunity.”36

Within four months of the sale of the Whitehill and Wright factories, local capital sustained yet another “severe blow.” The Kilmer Wire Works, which had been brought to Newburgh by the Board of Trade through a local subscription of $100,000 in capital stock, declared bankruptcy in October.37 The failure was precipitated by the major supplier of the Kilmer Works, namely the Troy Iron and Steel Company which no longer agreed to let its $106,000 account go unpaid. The Kilmer stockholders, mostly Newburghers, found their stock certificates worthless as the total debts of the firm rose to over $800,000:.38 Proclaiming it “the most disastrous failure ever known in Newburgh,” the public-spirited capitalists who had invested in the enterprise singled out the Board of Trade for “soaking them.”39 A major supporter of the venture was both vice-president of the Board of Trade and a large investor in local real estate; a partner of the firm that marketed the stock locally was found to be related by marriage to the Kilmer family, all of which increased Newburghers’ apprehensions. The Sunday Telegram observed that “the next man or organization that can float any stock around this town will have to be a freak.”40

Since it no longer appeared likely that local capital was either willing or able to direct Newburgh’s industrial recovery, Newburgh’s leaders looked expectantly to see what the absentee owners intended to do with the Newburgh factories. One leader predicted that with the sponsorship of wealthy New York syndicates, Newburgh’s iron and machinery firms would conduct operations of “gigantic” proportions.41 Gradually, however, these optimistic projections faded. The absentee owners of Wright’s retained only skeletal crews while the owners of the other two firms sold their patents, machinery, and inventories to non-local producers.42 Confronted with local judges who were more sensitive to the economic needs of Newburgh than the bankruptcy statutes, the creditors of Wright’s and Whitehill’s had purchased the bankrupt firms simply to supervise the disposition of their assets.

Optimism abounded over rumors that the Troy Iron and Steel Company, closely tied to Standard Oil, would take over Kilmer’s.43 The ambitions of·Newburgh’s industrialists and realtors appeared to be more than realized when the nation’s largest wire trust – the Washburn and Moen Company – acquired the Kilmer Wire Works in 1899.44 The optimism subsided when the Trust immediately released all of the firm’s salesmen and some of its machinists. The Wire Trust made its intentions explicit within several months: the Newburgh factory was to be dismantled. Soon afterward the machinery was removed and shipped to other parts of the country while the unusable remainder of the firm’s assets were “junked.” The Newburgh wire mill had been purchased solely to prevent others from using the facilities. An astonished Telegram concluded, “And so ends the desert mirage held out in the distant visions of hundreds of skilled mechanics and cottages filled by the families of contented working men.”45

In 1900 the Telegram observed. “It has taken Newburgh exactly seven years to strike bottom.46 The nation as a whole was well on the way to recovering from the depression of 1893 to 1897, but in Newburgh, the situation had scarcely improved. The census for that year confirmed that there had been no appreciable increase in the city’s population for the first time since the crisis brought about by the Erie Railroad in the 1840s. The iron and machinery business had “gone to pot” and recovery seemed unlikely since the wave of late 19th-century industrial consolidations had strengthened the position of the Pennsylvania and mid-Western competitors.47 The building trades, formerly the largest sector of Newburgh’s employment, were completely inactive. Ten years earlier nearly two hundred homes were built annually; but only three houses were constructed in 1899, and none through the first half of 1900.48 Rents declined sharply and one realtor lamented, “There is no real estate market to quote, and hasn’t been for a number of years.”49 The city’s more enterprising unemployed took to planting potatoes in the vacant lots of the city, and some fifty families were sustained by these rustic experiments in urban economics.”50

Those who had waited patiently for the city’s economic recovery began to give up hope. The city’s leaders – Wright, Whitehill, Delany, Kilmer. Beckman, Dickey and others – had been unable to save their own firms, much less rebuild the economic foundations of the entire city. Wright died penniless in a Brooklyn tenement. Whitehill, too, died shortly after his firm’s failure, and his brother was left to fight unsuccessfully for local control of the engine works. Ramsdell had divided the largest portion of his estate among his grandchildren thereby minimizing the extent to which his wealth could be immediately wielded for local enterprise after his death in 1895. Beckman was fired shortly after his gas and electric company had been absorbed by General Electric. And if local industrialists had proven incapable of orchestrating Newburgh’s economic revival, it now seemed doubtful that the various absentee owners would take on Newburgh as their charge.

These were the undercurrents, then, that the aforementioned Newburgher disingenuously omitted from his discussion with the traveler from Middletown in the autumn of 1900. Newburgh had indeed undergone a transition from a commercial town to a manufacturing city – that part of the tale was correct-but the “slowness” attributed to the city was largely a consequence of the fact that the industrial foundations of the city were collapsing. In boosting his city the Newburgher was perpetuating the tradition of localism established by the forwarding merchants nearly a century earlier. As the city’s factories were passing into the hands of disinterested absentee owners and distant corporations, and as the local leaders were becoming powerless to direct the city’s recovery, it was imagined that the spirit of localism would somehow breathe life into the city’s prostrate industries.

But even as the Newburgher was explaining (or dissembling) the ramifications of Newburgh’s transition to a manufacturing city, another metamorphosis was taking place. If the well-traveled Newburgher had visited the workers’ district in the southern portion of the city, he would have noticed the Italians, eastern Europeans, African Americans, and Russian Jews who were moving into the houses and tenements that had been all but abandoned during the depression of the 1890s. The most significant legacy of the Panic of 1893 – low rents and inexpensive housing – eventually furnished the basis for the city’s industrial rejuvenation by attracting immigrant labor. Newburgh’s garment factories and sweatshops, requiring little capital but ample supplies or cheap labor, flourished. Several clothing companies moved to Newburgh, often occupying the vacated premises of the iron and engine works.51

Once again Newburgh was to receive its share of progress. But just as some Newburghers were made uneasy by the clanging of the factory bell and the arrival of Irish immigrants in the summer of 1845, some Newburghers despaired of the alien newcomers at the turn of the century, imputing to them the rise in crime and corruption, the increasingly ramshackle tenements and overcrowded lots, and the growing sense of pessimism over the fate of the city as a homogeneous community. Some went so far as to reject the longstanding economic definition of progress, arguing that the garment factories should be closed. “These pauper labor concerns,” they claimed, “are a detriment to any town.”52

Industrial Newburgh began as a gamble – a desperate attempt by a close-knit group of merchants to protect their real estate investments. Conceived as an economic instrument and sustained by a pervasive commitment to local economic growth, Newburgh was unprepared at the beginning of the 20th century to question the consequences of industrialization. During the decades that followed, Newburgh’s garment industries prospered and subsequently faded; after World War II another massive demographic change transformed the city. Yet over the years, the willingness to regard the city as an economic contrivance remained unshaken.

The Book of Progress

Newburgh will have a population of 60,000 in 1950, and say 125,000 in the year 2000…. Cut this prediction and paste it in your hat. The logic of increase and development is irresistible. Nothing will arrest it in the natural order of things. It is written in the book of progress.

– Newburgh. Sunday Telegram, April 14, 1895

Animating the urban-industrial revolution of the 19th century America was a faith in progress – a conviction that the nation’s economic and social institutions were evolving to some higher form. Fired in the crucible of competition, the factories, railroads, banks, and even the individual entrepreneurs and their cities were the products of a vaguely understood Darwinian alchemy: the “fittest” survived and prospered, while those that were in some way deficient did not. Although this notion of competitive, evolutionary progress was applied broadly to many endeavors during the 19th century, it often achieved its most explicit expression in reference to the destiny of particular cities. Local newspaper editors, politicians, and promoters persistently conjured the specter of a ghost town – or at least the prospect of “falling behind” – to enlist public support for various developmental schemes. Americans, moreover, showed a remarkable willingness to part with their public and private funds to ensure the prospects of their town.

Why parochial attachment should be so strong in 19th century urban America is not self-evident, for American cities were made “in a few years out of nothing,” as Seth Low put it.53 While European parochialism was nurtured by deep-rooted traditions and ageless family ties, American cities were the setting of endless demographic upheavals.54 And if European parochialism was tempered by tradition, American localism took on a strident character: the huckster and booster were almost indistinguishable.

The fusion of these ideas – a faith in economic progress and a self-conscious sense of localism – decisively influenced Newburgh’s development during the 19th century. The emphasis on local economic growth, emanating from the marital practices and real estate investments of’ the freighters, shaped the mercantile village of the early 1800s and necessitated its industrial transformation at mid-century. Originally a device of the mercantile elite, localism became acceptable by all classes. Laborers and building tradesmen, comprising the largest segment of the labor force, recognized the need for unlimited growth to maintain their economic position. Middle-class families, whose status was confirmed by home ownership, sought population growth to protect their major investment. Similarly, the late 19th-century industrial parvenus, financed by the old forwarding merchants and elevated to positions of community leadership, gladly accepted the responsibility for ensuring the town’s growth. Closely identified with economic self-interest, localism thus became the unifying concept of 19th century Newburgh.

It was an idea, however, which became increasingly outmoded as the century progressed. Geographic specialization eroded the economic foundations of many small industrial cities such as Newburgh which lacked any particular competitive advantage. The extension of railroad track and the reduction in railroad freight rates during the last third of the 19th century favored the “efficiently producing centers over inefficient and nonproducing cities.55 In accordance with Adam Smith’s well-worn dictum, the widening of the national industrial market encouraged geographical specialization, much as the high transportation costs earlier in the century protected industrialists in one area from more efficient competitors elsewhere. The efforts of Newburgh’s forwarding merchants to create an industrial city in the mid-1800s succeeded partially because the industrial market was fragmented by high transportation costs. By the 1890s, however, Newburgh’s engine factories were buying iron castings from Ohio at a cost below that of local foundries.”56

The evolution of a national investment market during the last third of the 19th century57 further weakened Newburgh’s industries. Lance Davis has noted that in the early 1800s capital moved from one area to another “only when the savers themselves moved with their capital.”58 Newburgh’s forwarding merchants mastered this locally-oriented economic system. Through the practice of mercantile intermarriage, they consolidated local investment capital and channeled it into local turnpikes, hotels, real estate and finally into local industries. As non-local investments became accessible to Newburgh’s capitalists during the 1870s and 1880s, however, the elaborate system of local capital mobilization deteriorated. Forced to compete in the nation’s emerging investment markets, Newburgh’s industries began to suffer from a shortage of capital during the 1870s and 1880s, as suggested by a comparison of the value-added output per manufacturing worker for Newburgh and for the rest of the nation (see Table 5).

Table 5

Value-added by manufacture per worker, the United States and Newburgh (in 1879 prices)

| Year | U.S. | Newburgh |

| 1839 | 399 | ? |

| 1849 | 542 | 684 |

| 1859 | 605 | 613 |

| 1869 | 529 | 505 |

| (a) | ||

| 1896 | 521 | 505 |

| 1879 | 617 | 577 |

| 1889 | 900 | 77’2 |

(a)Robert Gallman emphasizes that because of qualitative changes in manufactured goods. it is senseless to compare value-added statistics over too great a time span; the data from 1839 – 1869 are comparable, as are the data from 1869 – 1899. One should not make comparisons between these two groupings.

Sources: U.S. data based on Robert E. Gallman, ap.cit.; Newburgh material based on Table 3 (page 46) and Appendix B.

During the period from 1849 through 1869, when Newburgh’s mercantile community was transferring capital into manufacturing. the output per worker in Newburgh was considerably above the national average. But by the 1870s and 1880s, the trend was reversed-an indication that relatively less capital was flowing into Newburgh’s industries. This failing became all too evident following the Panic of 1893.

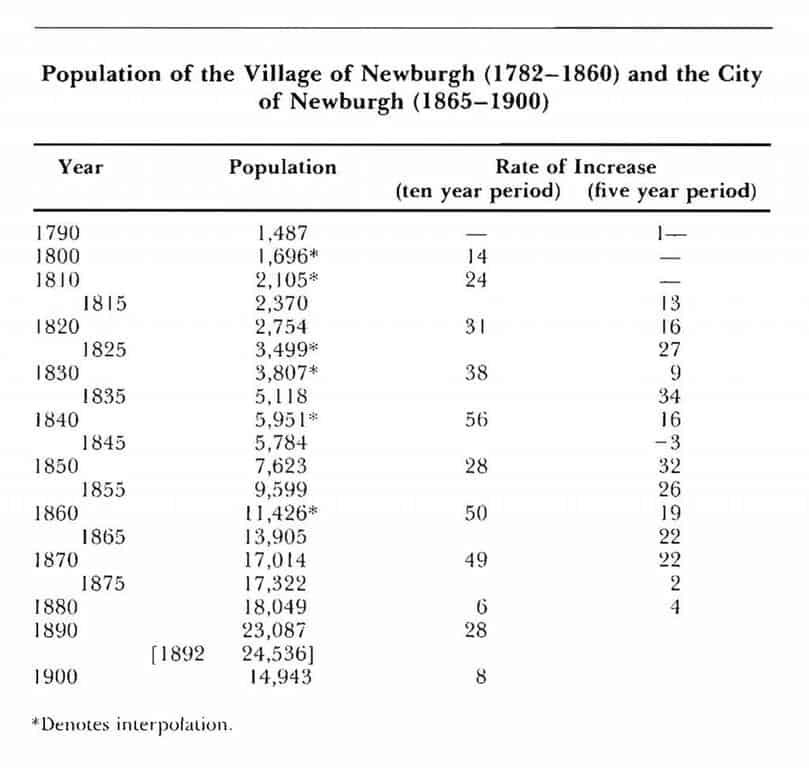

The pattern of Newburgh’s population growth relative to the rest of the Northeast paralleled the Row of capital into manufacturing (see Figure 1). Newburgh’s rate of growth when it functioned as a mercantile center had little in common with the average growth rate of cities in the Northeast; after the completion of the Erie Railroad, Newburgh’s loss of population from 1840 to 1845 (refer to Appendix A; Figure l does not include data from the New York State Census) was especially unusual. But as the forwarding merchants redirected their capital into manufacturing during the late 1840s, the 1850s, and the 1860s, Newburgh’s growth rate exceeded that of the region as a whole. By the 1870s, however, a new pattern was established – one that would last to the present: Newburgh grew at a rate consistently lower than that of most other cities in the Northeast.

Geographic specialization and the evolution of a national investment market were major elements in the economic rationalization of the nation during the last two decades of the 19th century. Yet economic progress, defined as increasing specialization, output and efficiency, eventually devastated the economic system established by the forwarding merchants.

“The economic significance of cities,” Shigeta Tsuru has written, “lies in the external economies they provide.” By “external economies” Tsuru means those benefits “which cannot be directly attributed Lo the action of the private individual firm,” such as a nearness to markets and complementary producers, and the availability of a large and specialized labor force.”59 As a small industrial city, however, Newburgh provided few external economies; it lacked a competitive advantage in proximity to raw materials or markets; its labor force was small and relatively unspecialized. That it became an industrial city at all is remarkable. But Newburgh’s forwarding merchants were not content to watch as outside economic forces overwhelmed their town in the 1840s. Their success in the creation of an industrial city stemmed in part from their ability to muster local resources – capital, entrepreneurship. and leadership– to compensate for a lack of external economies.

From the outset, however, the freighters’ foremost concern was the growth of their city rather than the profitability of their industries; both were clearly related, but the intent of the forwarding merchants must be considered the crucial causal factor: They chose to industrialize because they believed it the best way to further Newburgh’s urbanization – and their real estate investments. Their motives and methods were founded in an as yet ill-defined localism. That they succeeded in creating a prosperous industrial city demonstrated the strength of a well-coordinated nexus of local economic forces in the mid- 18OOs; that they ultimately failed indicated the extent to which a rationalized economy had pervaded the nation by the close of the century. The forces of a broad economic market now dictated the city’s future.”60

(This is the second part of a two-part article.)